Your cart is currently empty!

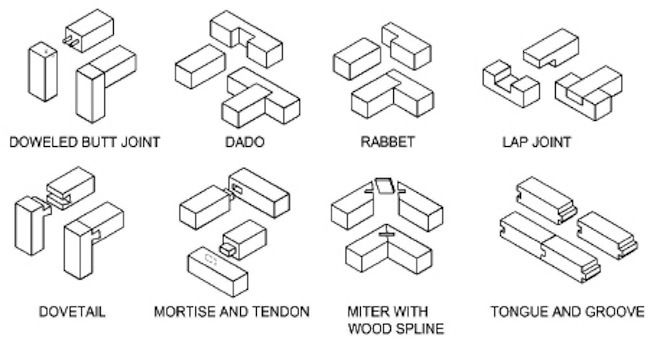

Types of Woodworking Joints

There are many different types of woodworking joints to choose from. These include pocket, bridle, butt, dovetail, and box joints. It’s important to understand how these joints work in order to build the best project possible.

Bridle joint

The bridle joint is a type of woodworking joint. It resembles the mortise and tenon joint but with the advantage of having a larger gluing surface. This gives the joint additional strength.

Using a bridle joint for a woodworking project is an easy process. Unlike a mortise and tenon, the bridle joint requires no nails or hardware. In fact, it’s a good choice for frames, narrow components, and home construction projects.

When making a bridle joint, you can use a table saw or hand tools to cut the tenon and mortise. However, you should be sure to get the right tools for the job. For instance, a sharp chisel is best.

Dovetail joint

Dovetails are a good choice for making corner joints, especially in woodworking, where the end result will be a tight joint that will not allow lateral movement. The process is relatively simple and straightforward, and it is often used in blockboard or plywood. A coping saw can be used to remove the excess material between tails.

Despite the name, a dovetail is not a true joint, but rather a “joint” that is thicker on the inside than on the outside. It is a strong joint that is hard to pull apart, but easy to pull together.

Using the proper tool and a little foresight, you can produce a solid and lasting joint. Typically, a dovetail will have two pieces: the tail piece and the pin piece. To create the best joints, you need to consider the type of wood you are using, as well as the amount of stress you are willing to put on it.

Box joint

Box joints are used in woodworking projects where two pieces of wood have to interlock in a corner. These joints are sturdy, simple, and can help accentuate your project visually. Whether you’re building a tool chest, an attractive cabinet, or a box for a child, these joints are a must.

The key to making a good box joint is to cut a groove as close to the inside of the joint as possible. You can use a jig, a dado set, or a table saw.

Traditionally, box joints were made by hand with a tenon saw and chisel. Today, fine cabinet makers still follow manual techniques, but modern machines can produce a full joint in one pass.

Butt joint

The butt joint is one of the most basic and simple woodworking joints. It is formed by joining two pieces of wood with glue and fasteners. These fasteners can be screws, nails, or dowels. However, it is important to ensure that the glue and fasteners are properly applied.

If a butt joint is not reinforced correctly, it can easily break with the strength of a pair of hands. This is why it is usually used on projects that do not need to withstand heavy loads.

Butt joints can be nailed, glued, or held together with dowels. Depending on the type of reinforcement you choose, they may be stronger than the wood they are made from.

Copped joint

The coped woodworking joint is a classic carpenter’s technique that is used for picture rail, chair rail and other moldings. It is made by making a cut in one piece of wood that is followed by a similar cut in another piece of wood.

Copped joints are typically used in woodworking projects that involve historic or traditional moldings. They are especially suitable for corners that don’t meet at 90-degree angles. This makes them more forgiving and less likely to reveal gaps as wood shrinks.

For a coped cut, you must use a specialty handsaw called a coping saw. You’ll need to make two cuts: a squared off cut and a cut that follows the contours of the molding face.

Pocket joinery

Pocket joinery is a great way to assemble structural frames, or to reinforce edges. It’s inexpensive and easy to learn. The best part is that you don’t have to worry about lining up the pieces or waiting for glue to dry.

You can use pocket holes to join wood pieces that have different grain orientations. They also work well with engineered materials like particle boards. However, the downside is that they are not as strong as mortise and tenon joints.

One of the most important aspects of a good pocket joint is the right choice of glue. Wood glue is inexpensive and common in shops. Another key aspect is selecting the right type of screw.

by

Tags: