Your cart is currently empty!

A Beginner’s Guide to Router Woodworking

A wood router is a piece of power equipment that can be used for a variety of tasks, including shaping wood edges, carving intricate designs, hollowing out grooves, cutting joints, and more.

A good wood router can make a lot of different jobs easier, from rabbeting joints to making flush trim on countertops and jigs. But it’s important to know some safety tips and how to use a router safely.

Variations

The router is a versatile woodworking tool, suitable for a variety of different operations and styles of joinery. It’s a powerful handheld tool that can be mounted on a table for more precise work.

A fixed base router is ideal for edging and shaping, while a plunge model is suited to deeper cuts. Many manufacturers offer both bases in a kit, where you swap the motor between them depending on the job.

Routers are used to cut a wide range of shapes and patterns in woodwork, including panel decoration such as banding, inlaying and escutcheon plates. They also produce a variety of decorative edges such as rebates, chamfering and edge molding.

The router is particularly suited to cutting circular shaped profiles, and there are many different types of cutter that can be used to produce this effect. Most are self-guiding, but some are angled to give a bevelled effect where two surfaces meet.

Safety

A router is a tool used to shape and finish edges, cutaways and contours. It is also used to create rabbets and dadoes.

Routing can be a dangerous process, and there are some basic safety measures to take when using one. These include wearing long pants, a long-sleeved shirt, closed-toe shoes, gloves, safety glasses, ear protection and dust masks.

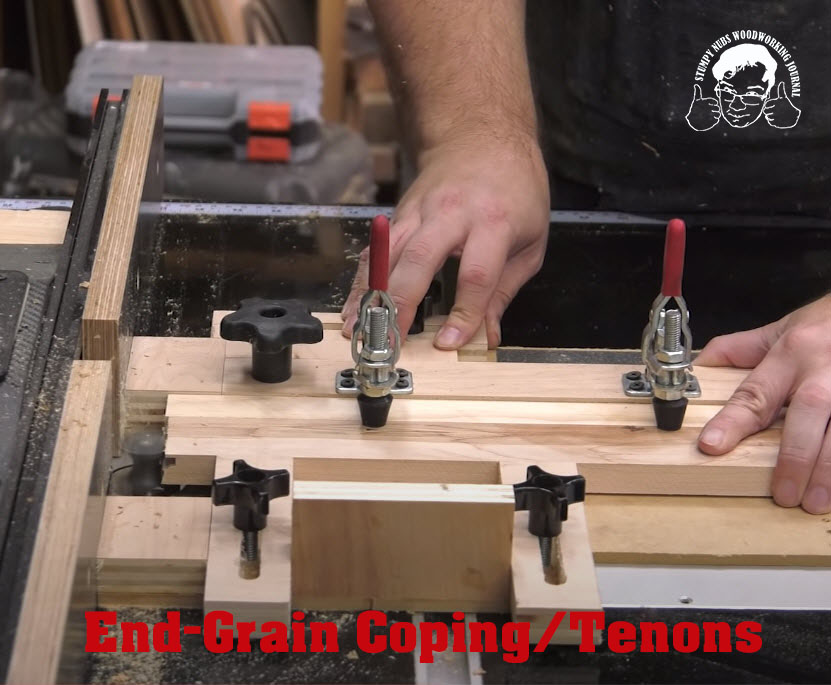

The type of material you are routing will have an impact on your safety. For example, end grain is a bit more prone to kickback and tear out than other types of wood.

To help reduce this risk, always rout against the fence with the board’s edge against it. This can prevent the board from trapping between the fence and bit, which can cause the router to hurl the wood.

If you are cutting a rabbet or dado, use the appropriate bit for the job and a rabbet guide that matches the workpiece’s profile. The rabbet guide helps the router achieve an exact match to the workpiece’s edge and produces a sharp and clean rabbet or dado.

Bits

There are a number of different types of bits used in router woodworking. They vary in style, shank diameter and price.

Flush-Trim Bits: These bits are ideal for achieving flush cutting edges, such as for veneered surfaces or pattern templates. They are guided by a pilot bearing that is the same diameter as the cutter, which can be located at the top, bottom or both.

Rounding-Over Bits: These bits create a rounded edge, which can add a decorative touch to your project. They come in single and double versions, with the single version creating just one rounded edge, while the double version cuts both the top and bottom of the material simultaneously.

Edge-Forming Router Bits: These bits produce various kinds of creative and decorative edging. These include Ogee, Beading and Cove bits.

They are typically computer balanced to reduce vibration and minimize kickback while producing exceptionally smooth roundover cuts. Carbide-tipped bits last longer and produce better results in all wood materials. HSS bits tend to dull more quickly and need regular inspections.

Maintenance

While routers are designed to work hard for a long time, they can be prone to failure if maintenance procedures are ignored. These short-term issues can be caused by a variety of factors, including improper operational practices or mechanical obstructions that hinder the router’s ability to perform its duties.

If your router’s motor is overheating, use a shop vacuum to clean out the air passages within the tool’s housing. This will help prevent sawdust from being sucked back into the machine and potentially damaging its windings and bearings.

Your cutters will need to be sharpened on a regular basis, especially if you’re machining wood with resin. If the cutter is dull it will slow the feed rate, cause chips to jam behind the flute and overheat.

Brush replacement in most routers is simple; just remove threaded plugs from the motor end cap to expose the brush holders, and replace them with new brushes. After replacing the brushes, blow away any carbon dust from the commutator and inspect it for wear or damage.

by

Tags: